As a professional metal envelope and steel structure products manufacturing service provider, wiskind has always been committed to innovation and development over the years. In order to pursue more environmental protection, lower total cost and higher thermal insulation performance, we independently developed purlinless system in 2020, developed the first design calculation program and construction node in China, and supported the project design and application with the only complete plate performance database independently tested in the industry.

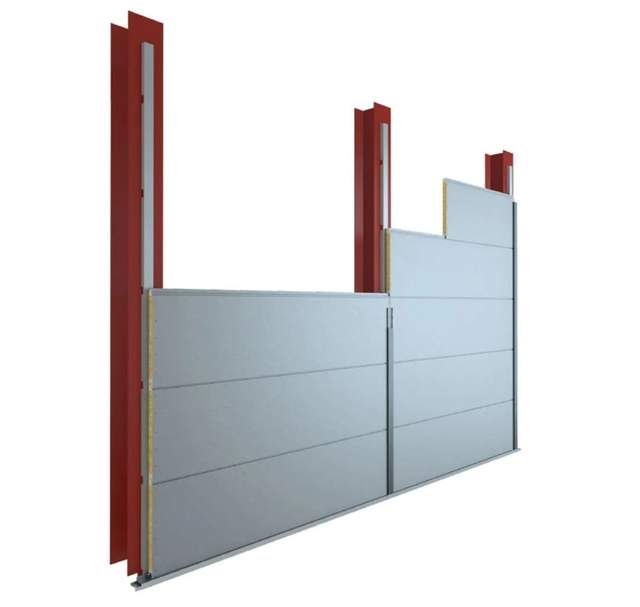

Purlinless system

The purlinless system is a wall system formed only by the combination of prefabricated element sandwich wall panel and structural column, in which the prefabricated element sandwich wall panel is connected to the structural column at the end by a screw through the plate surface. Each sandwich panel is a precast unit wall panel, the way of force transmission is clear and reliable.

► High economic adaptability

Purlins and linings are not required, which is more economical than purlin systems.

► Good heat preservation and insulation performance

The purlinless system has fewer thermal Bridges and higher insulation performance than the system with purlin.

► Less material consumption

No purlins and linings are required for exterior walls without purlins, reducing resource consumption.

► High utilization rate

Although the structural rock-wool sandwich is generally thicker than the one with purlin, the wall is thinner (the thickness of the sandwich is about half that of the one with purlin), and it can be used more efficiently for the same floor area.

► Efficient construction

Due to the lack of primary and secondary purlins and lining, and the prefabricated structure design, greatly improve the construction efficiency, shorten the construction period, reduce the construction cost.

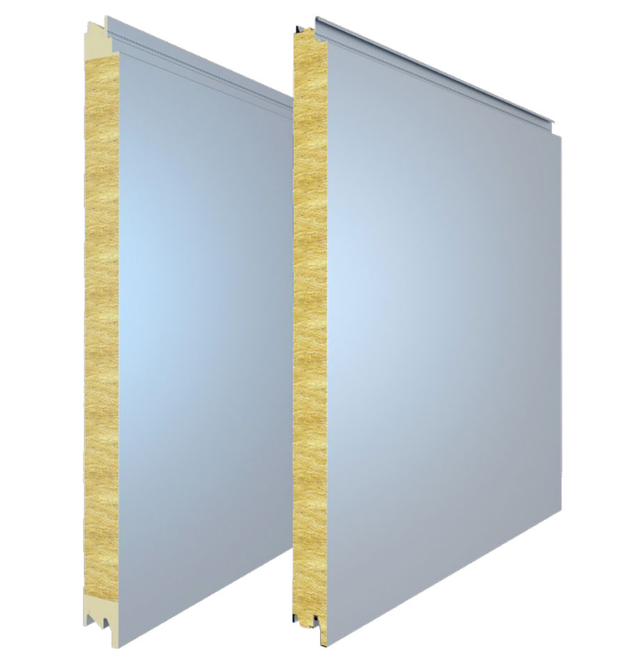

As the main material of the purlinless system, StrucRock sandwich panel can be perfectly matched with the wall without purlin system.

Wiskind strucrock sandwich panel are clad in color coated steel and core material is 95W Structural Rock Wool ™. This type of prefabricated unit wallboard has better economic cost, less material consumption, better mechanical properties, better thermal insulation, and faster construction and installation. When used as an outer wall without purlin system, the span/column spacing can reach 7-8 m.

► Sandwich board can be two-sided or four-sided tongue-board type, rock wool board type or edge sealing rock wool board type.

► Single span system and two span system are used, which can be applied to external wall or internal partition wall.

Mars Pet Food Tianjin base

▼

The construction project

▼

Wiskind R&D Center Building

▼

Hubei Yiwei Industrial Park

▼

Nowadays, with the concept of green architecture becoming more and more popular, prefabricated buildings are also widely used. The no-purlin system will be used in more projects due to its unique advantages.