Is there a flexible roof product, better than the traditional flexible roof insulation, construction faster; It has better insulation and waterproof performance than single layer metal roof. And waterproof than metal surface sandwich plate better at the same time, but also economic. "BiTOP® prefabricated membrane roof systems" can meet all the above requirements.

Product overview

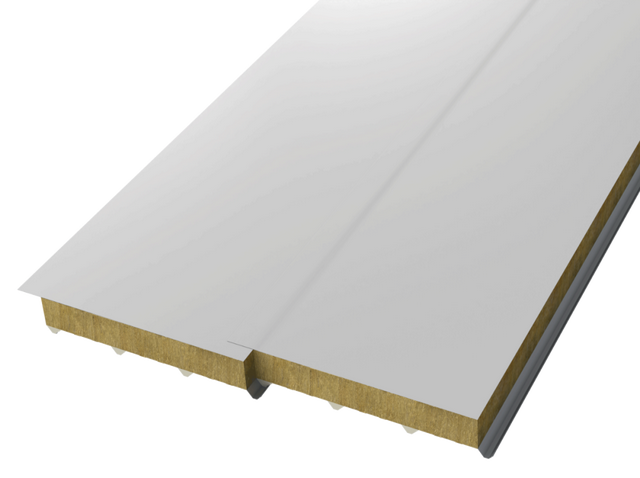

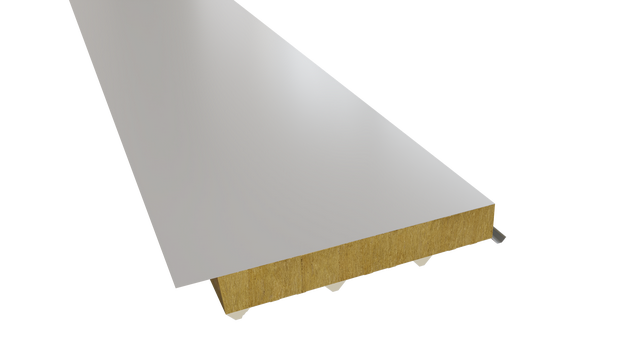

BiTOP® prefabricated membrane roof systems, developed by Wiskind and Oriental Yuhong, has been patented. It is a self-supporting composite plate composed of TPO coil and pressed steel plate as the surface layer, and a special rock wool core material bonded between the surface layer. Manufactured ON the continuous sandwich panel production line in the factory, it is a fabricated building material product with advantages of different materials.

The integrated panel is prefabricated by the factory, and the on-site installation process only requires three simple steps: positioning, napping and welding, bringing a new Angle to the metal sandwich panel roof!

Industry leading L - type TPO coil surface

Strong bonding performance, excellent welding performance, excellent weather resistance

BiTOP® selects Oriental Yuhong's leading TPO coil as the surface layer, which has excellent bonding performance with rock wool insulation material and excellent welding performance, ensuring long-term waterproof and reliable joints.

High quality rock wool core material

High strength grade A non-combustible

BiTOP® selects high-quality rock wool as core material, which can reach grade A noncombustible, compressive and stampede resistance, high bonding strength and high peeling strength.

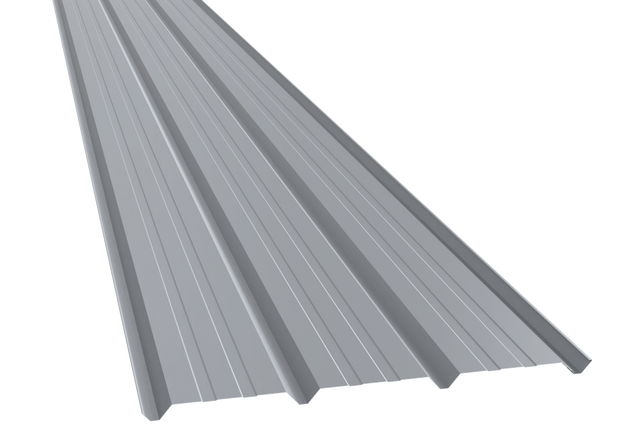

Pressed steel plate

Optimized cross section beautiful and efficient

BiTOP® base plate is made of high quality galvanized or aluminized zinc steel. The section characteristics of the molded steel plate give the sheet the performance of resisting the roof snow load and live load.

In order to meet the needs of indoor beauty and bright light, white color coated steel plate can also be used.

Strong insulation to create a comfortable space

The large number of fasteners and gaskets of conventional flexible roofing is a significant thermal bridge, while BiTOP®, no thermal bridge phenomenon, better insulation.

Preferably rock wool core material with excellent thermal insulation performance.

High wind resistance is not afraid of the wind swept

The minimum configuration is sufficient to meet the wind resistance requirements of most industrial construction projects, and even higher wind resistance requirements can be achieved by means of an infilled purlin or pin spacing.

Tailor-made special wind resistance design calculation program, based on various test data and specifications/standards for design calculation, to ensure the technical economy of roof design scheme.

Excellent waterproof rest assured roof

Installation process: BiTOP® waterproof coil surface layer is fully adhered to the rock wool, and the installation process is less, and the construction process is good waterproof.

BiTOP® roofing with photovoltaic solutions, on the basis of reliable waterproof, roof insulation performance is better, and can play the best photovoltaic module power generation efficiency.

Under the background of "double carbon", thousands of industries are changing towards green and sustainable direction. As an effective means to realize the green and high-quality development of the construction industry, prefabricated building has also stepped on the road of high-speed development.

As an important part of prefabricated building, prefabricated roof also plays an important role in prefabricated building. As a leading supplier of metal envelope products, mastercard has been committed to promoting green buildings for more than 40 years. Through the introduction of "BiTOP® prefabricated membrane roof systems", mastercard also hopes to reduce costs and increase efficiency for more construction projects, and contribute to the development of prefabricated buildings!