Polyurethane (PU), the full name of polyurethane, is a kind of high molecular compound. It appeared in the 1930s and was developed by German scientists. After nearly 80 years of development, it has been widely used in the field of architecture, household, daily necessities and so on.

Polyurethane products mainly include the following: foam plastic, elastomer, fiber plastic, fiber, leather shoe resin, paint, adhesive and sealant, among which foam plastic accounted for the largest proportion.

Classification of polyurethane foam plastics

Polyurethane foam is mainly divided into two types: hard foam and soft foam.

Soft foam: Soft polyurethane foam is the largest amount of polyurethane products, generally has low density, good elasticity recovery, sound absorption, air permeability, heat preservation and other properties, mainly used as a cushion for living rooms, vehicles, clothing.

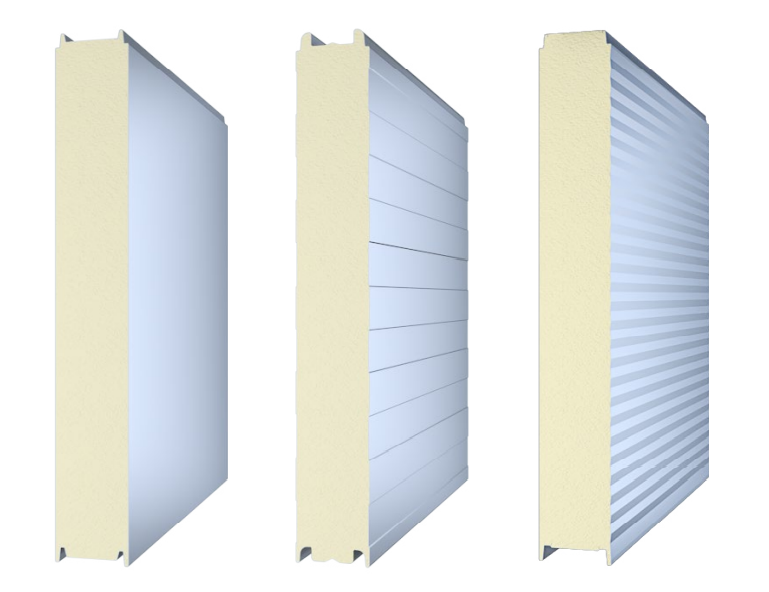

Hard foam: polyurethane sandwich board is common in our construction projects. The core material is rigid polyurethane foam plastic, which has the characteristics of light weight, good insulation effect and good durability.

The lower density of hard foam polyurethane is mainly used as heat insulation (insulation) material, the higher density of hard foam polyurethane can be used as structural materials (wood imitation). Hard foam polyurethane thermal conductivity than that of polystyrene and other plastic foam and natural low insulation materials, insulation performance is good, and can be on-site pouring or spray forming, and the heat preservation material combined into an organic whole, make the heat preservation effect better, therefore, in the field of heat preservation and heat insulation, polyurethane foam plastics is the preferred material, a wide application.

Wiskind cold storage panel

Wiskind cold storage insulation panel, and BASF jointly made. It is made of BASF's new pentane foaming B1 Elastopir® system. Elastopir® polyurethane insulation provides excellent thermal insulation properties. Cold storage with this insulation board can save up to 95% energy and minimize food waste.

At the same time, it also has ultra-high temperature stability and fire rating, can meet the latest Chinese regulations for B1 foam core material fire safety key regulations.

Excellent polyurethane foaming process

In the foaming process, polyurethane flows out from the mixer outlet in the form of uniform laminar flow. The rod can ensure the uniform distribution of the liquid reaction mixture and obtain a very flat foam surface.

And the temperature of polyurethane foaming is strictly controlled. The time, temperature and speed of foaming can be adjusted according to the sandwich board with different thickness.

Conclusion

This cold storage insulation board, jointly created by Wiskind and BASF, is most commonly used in the roof and wall materials of industrial buildings, which can achieve the best insulation effect without the thermal bridge effect. It helps keep cold storage at optimal temperatures, providing optimal storage conditions for food along the entire value chain, from farms to retailers.