The definition of prefabricated cold storage

The assembled cold storage enclosure system has a great impact on the operation energy consumption of cold storage. This is because the assembled sealing degree and material performance of the enclosure system play a decisive role in the thermal insulation performance of the building. The construction unit must choose the construction party with the cold storage engineering construction qualification and familiar with the material characteristics. Wiskind Energy-saving Materials Co., Ltd. is an ISO9001 and ISO14001 certified enterprise, a first-class qualification enterprise of steel structure engineering contracting, a first-class qualification enterprise of steel structure engineering design, a first-class qualification enterprise of steel structure manufacturing, a top 30 Chinese steel structure enterprise and a AAA credit enterprise recommended by the Chinese steel structure industry. With more than 40 years of industry experience and resource advantages. We provide materials and construction services for many industries including biopharmaceutical, aerospace, food processing, animal husbandry, cold chain fresh and so on. We are a reliable quality manufacturer.

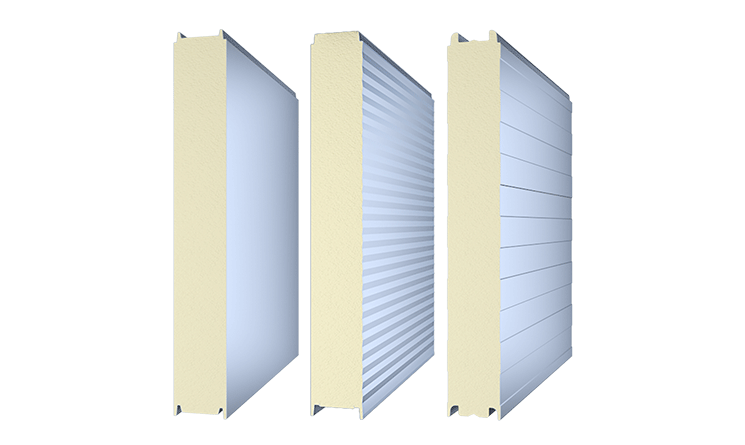

What are the components of the assembled cold storage enclosure system? First of all, we make clear the definition of prefabricated cold storage: prefabricated cold storage is composed of heat insulation wall panel, roof, bottom plate, door, support plate and base, through the special structure of the child hook assembly, fixed, so that it can achieve heat insulation, moisture-proof and cooling performance requirements of a cold storage building.

Enclosure system of prefabricated cold storage

The enclosure system of assembled cold storage mainly includes three parts: ground, roof and wall. The ground enclosure of cold storage mainly considers the cold conduction effect between the indoor low temperature environment and the core of the building or the overhead layer. The floor heating system is usually used to solve the anti-frost heaving problem of the floor in the cold storage room. The roof enclosure system of cold storage adopts composite insulation combination roof, that is, the metal surface bearing board is laid with insulation layer, steam insulation layer, fire isolation layer and waterproof layer; The wall enclosure system of cold storage is generally metal surface hard polyurethane sandwich board, which is a prefabricated building component that combines the good mechanical strength of metal plate with the excellent heat insulation and insulation performance of polyurethane foam. It is an ideal insulation enclosure material for cold storage, widely used in cold storage buildings.

According to the test: the heat transfer of the enclosure system accounts for 20%~35% of the total heat load of the cold storage, therefore, the selection of the enclosure system is very important. Wiskind Energy-saving Materials Co., Ltd., research and development of COLORSPAR® Sandwich Panel, to a new generation of PIR pentane B1 polyurethane foam for hard core material, has excellent high and low temperature stability and higher fire rating, effectively reduce energy consumption of cold storage operations, enhance energy efficiency, is a rare prefabricated cold storage enclosure system components.