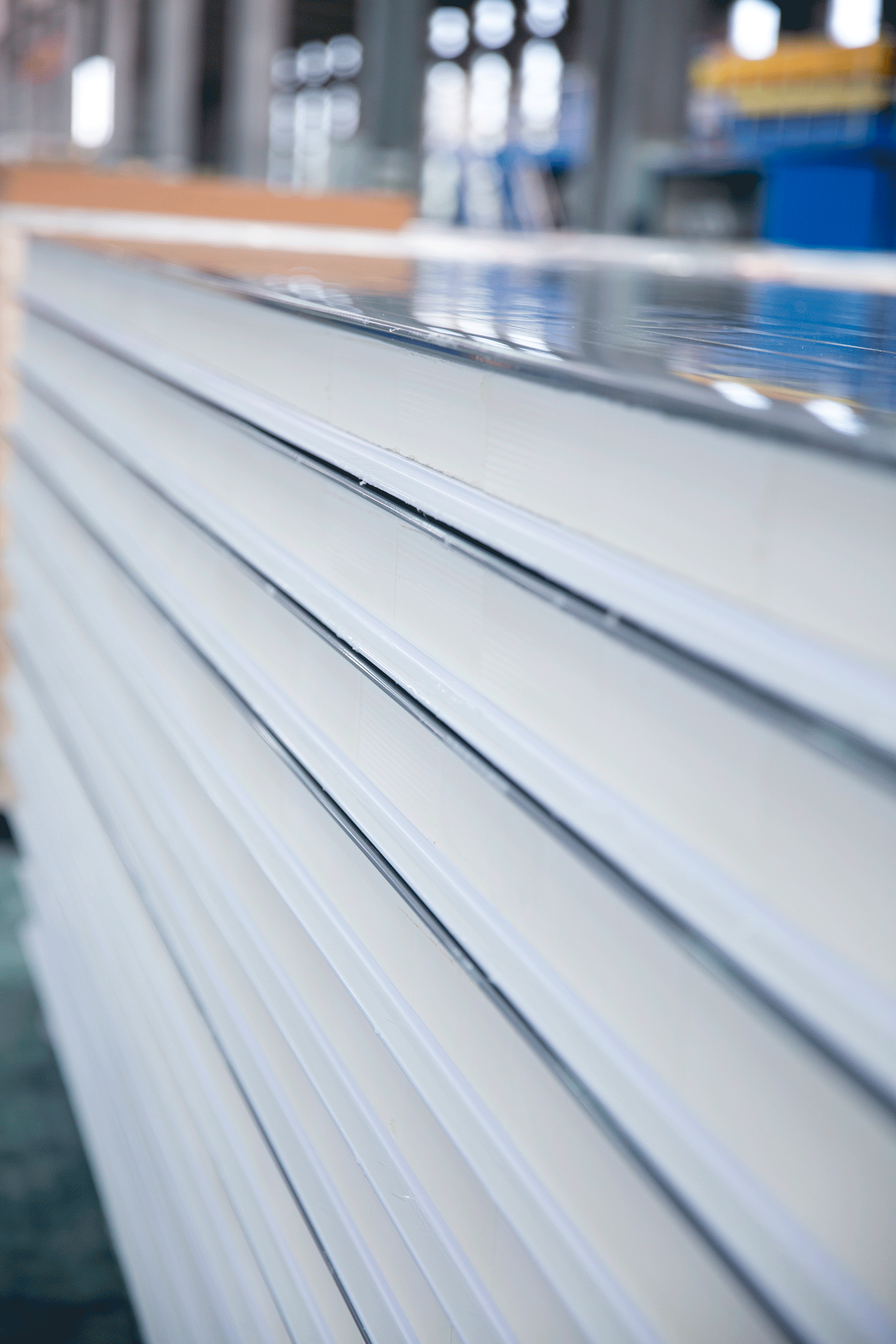

Shandong Wiskind Architectural Steel Co., LTD. has been focusing on the business of energy-saving heat insulation materials for cold storage enclosure system for many years. Through the new generation polyurethane PIR pentane B1 core material formula and scientific node design, we provide customers with a complete solution from processing to storage. Its production of COLORSPAR® Sandwich Panel has high mechanical strength, strong insulation performance, to meet the national B1 level fire prevention requirements, is a new generation of environmental protection quality building materials.

Cold storage enclosure system In order to maintain the low temperature environment of cold storage, in addition to the use of refrigeration system to continuously provide cold capacity to the interior, it is necessary to prevent the outside heat from infiltrating into the cold storage. The data show that the heat transfer of the insulation layer accounts for 20%~35% of the total heat load of the cold storage. It can be said that the quality of the cold storage board directly affects the energy consumption of the cold storage operation and maintenance.

The composition of cold storage board

At present, the most common cold storage board in the market is a composite plate made of metal outer plate and polyurethane sandwich. It is a prefabricated composite building component that organically combines the good mechanical strength of metal plate with the excellent thermal insulation and insulation performance of polyurethane foam. Metal plate materials are generally color steel plate, galvanized steel plate, aluminum plated zinc steel plate, stainless steel plate, aluminum alloy plate, etc. Sandwich layer materials are generally polystyrene foam (EPS), extruded polystyrene board (XPS) and polyurethane (PU), etc. At present, the most widely used, the best quality is polyurethane sandwich material.

The characteristics of the cold storage board

Cold storage plate is composed of metal and polyurethane, which has the advantages of light weight, good rigidity, high strength, compact structure, quick installation, beautiful health and so on.

What is B1 grade polyurethane cold storage board?

The so-called B1 level standard is to divide building materials into class A (non-combustible materials), Class B1 (refractory materials), class B2 (combustible materials), and Class B3 (flammable materials) according to their flame-retardant ability.

So what is the B1 cold storage board? The oxygen index of the B1 grade cold storage board, namely the polyurethane sandwich layer, is more than or equal to 30. In the self-extinguishing test, it can not ignite, atrophy at most, and self-extinguishing within three seconds after leaving the fire source. Self-extinguishing test is also very simple, with the manufacturer to ask for a cold storage board sample, with a lighter self-test can be.

That is to say, to meet the B1 level inflammable standard stipulated by the state, it can be called B1 level polyurethane cold storage board.